Starter motors are incredibly convenient pieces of engineering. Instead of having to use a hand crank to start your car, you can just turn a key or press a button, and voilà, the engine starts. But how does a starter work? Thanks to this custom see-through starter motor built by the Warped YouTube channel, we can see for ourselves.

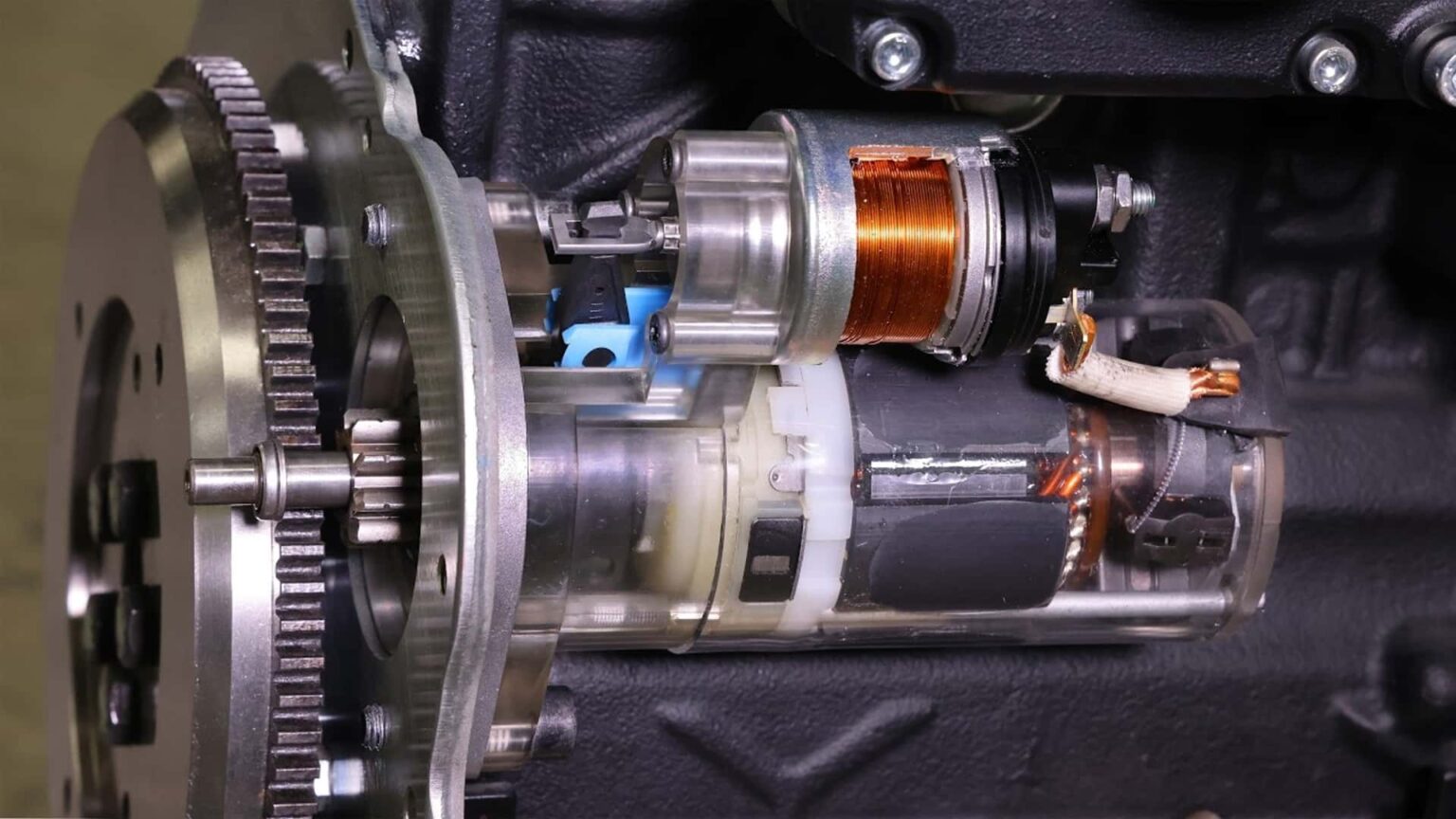

Using a 3D printer, Warped is able to replicate the body of a starter motor for a Kohler turbo-diesel engine. The insides of the motor are moved from the original casing to the clear body, giving us an uninterrupted look at all of the inner workings.

From there, we can see the main motor assembly, which uses permanently secured magnets to spin a centrally mounted copper coil. When electricity is introduced, the motor spins, while a solenoid attached to the top of the motor engages a lever that pushes the starter gear forward, allowing it to make contact with the flywheel.

The slow-motion camera gives us an excellent view of all the starter’s functions as they happen. Sadly the torque breaks off a chunk of the 3D-printer plastic body, but as a concession, we get an uninterrupted view of the starter gear as it reaches out and spins the flywheel.

Warped’s 3D-printed body can’t handle spinning the whole engine, so it’s eventually swapped out for a normal starter motor. The channel eventually tries running the starter motor with the flywheel already spinning, showing what would happen if you tried to start a car that’s already running. Unsurprisingly, it results in a bunch of metal shavings flying everywhere.

Read the full article here