Hybrid powertrains are an essential part of Nissan’s comeback plan. The automaker will soon release its third-generation E-Power system, which uses an internal-combustion engine purely as a generator, with an electric motor driving the wheels on its own.

With that, Nissan aims to eke the most efficiency out of its new hybrid powertrain as possible. Advanced manufacturing techniques could make that possible.

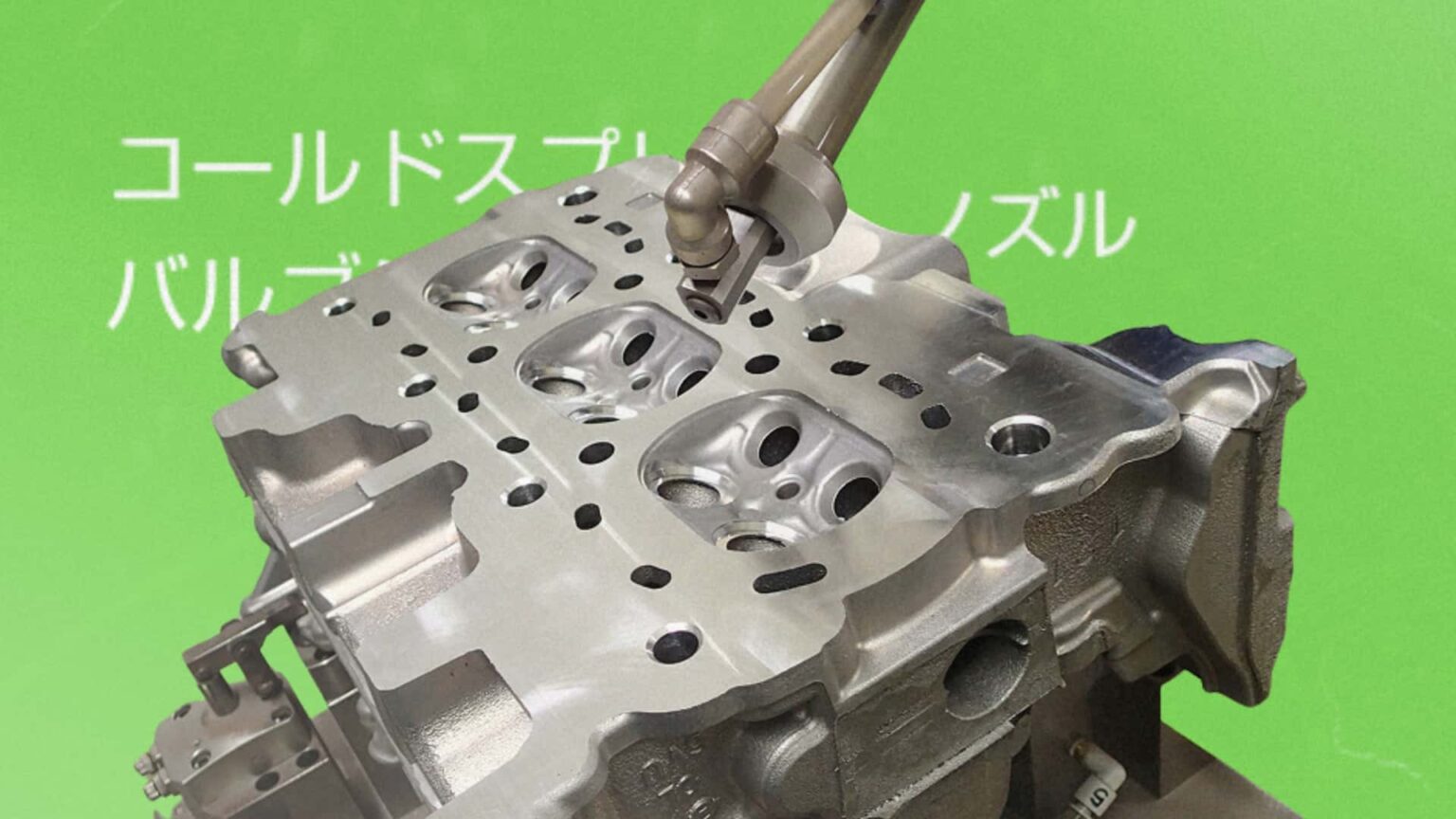

Nissan says its upcoming ZR15DDTe engine is the first in the world to use valve seats that are cold-sprayed directly onto the cylinder head, rather than seats that are pressed into place. The idea is to create an intake port shape that reduces the turbulence of the air flowing into the combustion chamber, helping create the ideal tumble flow and simultaneously boosting efficiency.

Nissan claims 42 percent thermal efficiency for this engine, which beats out the 41 percent that Toyota and Hyundai have both claimed for their hybrid engines. The only more thermally efficient internal-combustion engines out there are Formula 1 power units, which push past the 50-percent mark thanks to their use of electric turbochargers.

Photo by: Nissan

Cold spraying is a form of manufacturing in which powdered metals are bonded and sprayed onto a surface. In Nissan’s case, the alloy is copper-based, and it’s sprayed at supersonic speed onto the cylinder head.

This sort of manufacturing has been around for a few years now in other industries, but it’s only just making its way into high-volume auto manufacturing. Nissan also says the alloy it uses for the valve seat improves cooling performance at the valves, thanks to its high thermal conductivity properties.

Nissan has a patent on this technology, which it applied for in 2020 and received this past April. The head has a specific design to accommodate these sprayed valve seats, which ensures the required strength.

You can’t just use a cylinder head designed to use press-fit valve seats and spray in these seats instead.

Photo by: Nissan

Photo by: Nissan

If you’re a frequent Motor1 reader, you might know about Nissan’s troubles with new engine technology. Its much heralded VC-Turbo variable-compression engine has proven a disappointment, with its added mechanical complexity creating durability issues and forcing Nissan to issue a massive recall. And all for minimal improvements to fuel economy and performance.

This is different, though. Nissan isn’t adding components to an engine here, as it did with the variable-compression mechanism in the VC-Turbo—it’s just changing the design and manufacturing of a common engine component to get a bit more efficiency.

Nissan says this engine will make its North American debut in the upcoming fourth-generation Rogue, which should arrive in 2027. If all goes as planned, Nissan’s new hybrid powertrain could be a game-changer.

Read the full article here